We have to cancel the race at Gardermoen There was to little time to work getting the bike ready, finding the problems we have and travelling. The weather in Norway was bad and if we had worked day and night to be there we have had been disappointed because of the bad weather.

We decide in an early stage to repair the bike and try to figure out what is wrong. We know that there is no mechanical problems but we do get a lot of mechanical damages when we are torching the heads.

By a discussion in the team and with people around us we find out that there are some areas that we have to make modifications to eliminate the risk of failures.

What we also decided was to cancel the Europen Finals at Santa Pod. We wanted to do testing before season is over and that must be on a good safe track - like Santa Pod - but we find out that we had one closer and that was in Alastaro in Finland the weekend before England. FHRA did run their finals. We did contact Tapio Valia in Finland and FHRA and they wish us welcome to come over for testing.

So, with the bike in perfect shape did Greger Johansson, Matte Tärnström, Carina and me go by the boat over to Finland. The weather was perfect all three days. Only one round was cancelled because of light rain. We did burn a lot of fuel during 16 warmups in the pits, adjusting and checking. The engine did run much better on idle and the response was there too. We did three shorter test runs, one per day. No sign of torching heads. But we got misfiring on front cylinder under load from the first round and by adjusting and checking we got less misfire every round. We couldn´t get rid of it before the weekend was over. But anyhow did this test weekend give us a lot. A very big thanks to FHRA letting us be there.

We did watch the race in England on the internet and for us that needed to get runs were glad we did get them in Finland. We did see many racers doing very good ET:s at Sunday mornings qualification and it was really exciting to follow the races and counting points. Congratulations to Svein-Olav Rolfstad who became 2008 Super Twin European Champion. There are many that is going to chase him next year.

Must mention Sverre Dahl Norway that now is running the new Karling/McBride clutch and setting a new European Speed Record with 371,93 km/h (231,11 mph) in Top Fuel Bike.

torsdag 18 september 2008

torsdag 14 augusti 2008

July 25th to 27th 2008 Mantorp Park Sweden Veidec Festival

Photographer Tapio Valja

Photographer Tapio Valja  Photographer Tapio Valja

Photographer Tapio Valja

Photographer Thomas LePrince

After Finland the torched head was repaired and the bike cleaned from the bottom to the top. It had aluminium sprayed over many components that has to be removed. Engine and transmission was totally disassembled for inspection and cleaning. The head seal was modified for more efficient transportation of heat. New Pushrod balls in the Uddeholm Vancron 40 was made and installed for testing. Greger Johansson who is taking one year off the racing, busy with building new engines, has been with us in the team this season. He is an expert in sheet metal works and did reshape the intake tubes for better more rigid mounting in the future.

We had a wonderful weather in Mantorp, up to 30 degrees C. At Thursday before the race had Leif Andreasson organized a MSD and Racepak on track training. Over 100 people did participate. Joe Pando MSD and Tim Andersson Racepak did an excellent job at the presentation and could give all answers on the tricky questions that came up.

As previous year did Super Twin Top Fuel and Top Fuel Bike run 1/8 mile on Mantorp because of the short stopping distance. New for this year was 1000 feet for Top Fuel Cars same length as NHRA start with in the Denver race this year.

Friday morning early, time for qualification for the Super Twins. We got big expectations and with the shorter distance we can try to find a “window” for our tune up without destroying to much parts. But we got the same problem again, torching the head direct after the hit. The team took a quick decision. We have to fix it for Saturday´s qualification. There is something in the tune up, fuel mixture, ignition, comp ratio, boost that not is right. Mechanical there is nothing to do except for maybe some smaller design changes. Nothing breaks it just torches.

Just before noon Charley and Jarmo borrowed a car and drove 2,5 hours home with heads and cylinders. Matte, Greger and Göran “Spex” Lönnmark did stay at the track cleaning up the bike and fix, inspect and replace parts.

In the teams workshop a new rear cylinderhead was completed and made ready for use with seats and guides, machining for nozzles and head seal and porting. Three more head studs were added in the hot area on both heads. The front cylinder head also needed seal fresh up because of smaller burn marks. The cylinders got the extra holes for the new studs. After a contact with Chris Brown at ARP did we choose studs and torque values to optimize the mount of the heads. The pistons were modified for lowering the comp ratio and with support from Tom Prock at Venolia did the top of pistons machined in shape to be optimised for nitro.

After 16 hours in the shop, eight a clock in the morning, did Charley and Jarmo drove back to Mantorp. At the track did a lot invited guests and sponsors have a lot of questions and also big expectations and hope too see the bike running down the track. Carina took care of all guest and the guys could assemble the bike. We missed the first qualification pass because the bike was not ready in time. After a warm up in the pits and small adjustments did it seems to run very well. Ready for last chance to qualify.

Time to make the run. Now the engine does not sound as good as it did in the pits, runs almost only on one cylinder. It cleans up during the burn-out and revs easily 6500 rpm at 20% throttle opening. Down to idle again, still running bad. What is the option, we have had been running fairly good with the old bike also starting with bad idle and this is the last chance to qualify. It is worth a try.

As soon as Charley open the trottle did aluminium from the front cylinder head spray out in huge flame and the last bend of the intake manifold also came loose. Big disappointment in the team. After all hard work and still similar problem.

We have been backing off on the tune-up as much as possible within the possibility of the design and when checking the logger everything looks great, except for the bad idle of course and that was even worse this last run at Mantorp.

At the elimination day did the team got the time discussing what to do and what possible can be done to solve the problem. The flame temperature must be lowered.

By talking with other teams at the track and see and compare logged runs and discuss design solutions we did collect as much info as possible to go on with our own bike. The positive thing with the overload of the engine parts we have experienced has been a continues development of the design in some areas that we will have good use for in the future.

Svein-Olav Rolfstad won the final at Mantorp and is now in the lead in the Championship.

We had a wonderful weather in Mantorp, up to 30 degrees C. At Thursday before the race had Leif Andreasson organized a MSD and Racepak on track training. Over 100 people did participate. Joe Pando MSD and Tim Andersson Racepak did an excellent job at the presentation and could give all answers on the tricky questions that came up.

As previous year did Super Twin Top Fuel and Top Fuel Bike run 1/8 mile on Mantorp because of the short stopping distance. New for this year was 1000 feet for Top Fuel Cars same length as NHRA start with in the Denver race this year.

Friday morning early, time for qualification for the Super Twins. We got big expectations and with the shorter distance we can try to find a “window” for our tune up without destroying to much parts. But we got the same problem again, torching the head direct after the hit. The team took a quick decision. We have to fix it for Saturday´s qualification. There is something in the tune up, fuel mixture, ignition, comp ratio, boost that not is right. Mechanical there is nothing to do except for maybe some smaller design changes. Nothing breaks it just torches.

Just before noon Charley and Jarmo borrowed a car and drove 2,5 hours home with heads and cylinders. Matte, Greger and Göran “Spex” Lönnmark did stay at the track cleaning up the bike and fix, inspect and replace parts.

In the teams workshop a new rear cylinderhead was completed and made ready for use with seats and guides, machining for nozzles and head seal and porting. Three more head studs were added in the hot area on both heads. The front cylinder head also needed seal fresh up because of smaller burn marks. The cylinders got the extra holes for the new studs. After a contact with Chris Brown at ARP did we choose studs and torque values to optimize the mount of the heads. The pistons were modified for lowering the comp ratio and with support from Tom Prock at Venolia did the top of pistons machined in shape to be optimised for nitro.

After 16 hours in the shop, eight a clock in the morning, did Charley and Jarmo drove back to Mantorp. At the track did a lot invited guests and sponsors have a lot of questions and also big expectations and hope too see the bike running down the track. Carina took care of all guest and the guys could assemble the bike. We missed the first qualification pass because the bike was not ready in time. After a warm up in the pits and small adjustments did it seems to run very well. Ready for last chance to qualify.

Time to make the run. Now the engine does not sound as good as it did in the pits, runs almost only on one cylinder. It cleans up during the burn-out and revs easily 6500 rpm at 20% throttle opening. Down to idle again, still running bad. What is the option, we have had been running fairly good with the old bike also starting with bad idle and this is the last chance to qualify. It is worth a try.

As soon as Charley open the trottle did aluminium from the front cylinder head spray out in huge flame and the last bend of the intake manifold also came loose. Big disappointment in the team. After all hard work and still similar problem.

We have been backing off on the tune-up as much as possible within the possibility of the design and when checking the logger everything looks great, except for the bad idle of course and that was even worse this last run at Mantorp.

At the elimination day did the team got the time discussing what to do and what possible can be done to solve the problem. The flame temperature must be lowered.

By talking with other teams at the track and see and compare logged runs and discuss design solutions we did collect as much info as possible to go on with our own bike. The positive thing with the overload of the engine parts we have experienced has been a continues development of the design in some areas that we will have good use for in the future.

Svein-Olav Rolfstad won the final at Mantorp and is now in the lead in the Championship.

July 4th to 6th 2008 Alastaro Finland Nitro Nationals

At the Main Event we found problems getting the tappet adjusting screws. The lock nuts can not take the load. So we made new more rigid screws and nuts in Uddeholm Orvar Supreme and hardened them up to the right level. We also sized up the Push Rods with thicker wall Chrome Moly tubes.

At the Main Event we found problems getting the tappet adjusting screws. The lock nuts can not take the load. So we made new more rigid screws and nuts in Uddeholm Orvar Supreme and hardened them up to the right level. We also sized up the Push Rods with thicker wall Chrome Moly tubes.First qualification. The bike really sounds strong and runs clean in the burnout. But at the sharp hit – for the first time ever with the bike - the intake tube came loose from the Y-intake between the cylinders.

Second try. After a deep check on bearings, pistons, cylinders and more. Now with

A better clamp for the intake tube. The intake tube came loose again but not direct on

the hit. Rolling to the finish line.

Third qualification. Flanges for the hose is made at the intake manifold and stronger clamps installed. A soft leave from the line 1,22 at the 60-foot, Charley leaves the trottle open to approx 300 feet as planned. The bike seems to be stable and easy to handle.

Fourth qualification. A 660 to 1000 feet is planned. But when Charley open the trottle did a spectacular flame come out from the rear cylinder. It torched the head on the left side. We had the first alternate spot in the ladder but realized that we not were able to repair the damages and fix the problem in a proper way at the track.

Lorenz Stauble was no 1 qualifier with a 6,76 and 342 km/h. The no 4 qualifier Svein-Olav Rolfstad won the race after have been running consistence all weekend with ET:s down to 6,6´s. Runner up was Hans-Olav Olstad also from Norway. Both guys are competing for in the same club.

fredag 13 juni 2008

11 June 2008 ROTERA KULLAGER 10 YEARS AND NOMO KULLAGER 60 YEARS

Around 300 people did show up during the celebration of 10 and 60 years in business for the two companys supplying the Scandinavian industry with bearings. Nomo is Swedens largest independent importer of bearings and has almost 19 000 different articles in stock.

Now 10 years ago did Rotera start in the same building as the head office of Nomo Kullager servicing customers over the counter. Since the start has Rotera had a quick grooving customer base. The company are very well known for the high grade of knowledge and support regarding bearings, sealings and transmission technology.

“ We are very lucky having these companies close to were we have our race-shop because it gives us the ultimate access to Timken, Torrington, Nachi, and other brands of bearings we needs. Also the support we got in designing our racing components thinking of selection of bearings and seals”, says Charley Karling.

Now 10 years ago did Rotera start in the same building as the head office of Nomo Kullager servicing customers over the counter. Since the start has Rotera had a quick grooving customer base. The company are very well known for the high grade of knowledge and support regarding bearings, sealings and transmission technology.

“ We are very lucky having these companies close to were we have our race-shop because it gives us the ultimate access to Timken, Torrington, Nachi, and other brands of bearings we needs. Also the support we got in designing our racing components thinking of selection of bearings and seals”, says Charley Karling.

tisdag 10 juni 2008

7 June 2008 CUSTOM BIKE SHOW, NORRTÄLJE SWEDEN, SCANDINAVIAN CHAMPIONSHIP IN CUSTOM BIKE BUILDING

Over 14 000 people did enjoy the 2008 Custom Bike Show in Norrtälje, Sweden. Around 250 bikes did compete in 6 classes for a price table worth almost a 500 000 sek. This show is also where a jury choose a winner that goes direct to the World Championship of Bike Building in Sturgis USA. The number two and three goes to the European Finals in Germany. The winner was Andy, Flying Choppers Finland.

Over 14 000 people did enjoy the 2008 Custom Bike Show in Norrtälje, Sweden. Around 250 bikes did compete in 6 classes for a price table worth almost a 500 000 sek. This show is also where a jury choose a winner that goes direct to the World Championship of Bike Building in Sturgis USA. The number two and three goes to the European Finals in Germany. The winner was Andy, Flying Choppers Finland.At one of the first times Charley did visit Custom Bike Show was 1974 riding his 1947 74” H-D Flathead Chopper with approx 5-10 hp over the stock 35 hp with it´s relived cylinders and tuned exhaust. At this years show did Charley and the team fire up the new dragbike that got some more power. Three warm-ups with Charley wacking the trottle 30-40% gave a enormous response. Most of the time did the team keep the bike undressed to give time for the visitors to see how the bike is built. Charley, Mats and Carina did answer questions all day long.

måndag 2 juni 2008

May 24 - 26th 2008 Main Event Santa Pod England

For the first time on the track with the new bike.

It has been a long way, from idea, planning, designing, chasing parts and manufacturing to get there, the first time open the trottle at the track. The list of involved people is so long that it needs a separate story to describe how the work has been done and by whom.

Two days before the event was spent in the pits by the team starting and testing systems and set-ups. The team was Jarmo Pulkkinen, Mats Tärnström, Carina and Charley. Hans Björkman, machinist and inventor who has spent days and nights in the Karling workshop together with Mats and Charley, stayed at home following the event. The Super Twin Rider Greger Johansson was also in team for the weekend and will also be so in Finland. Greger is making new engines and will be out later during the summer. Christian and Viktoria now with the little daughter Liv and changes in work situation do not have the time to spend the time that is needed.

We did miss the first qualification session because we did not get the right temperature at the rear cylinder. On the second session we were out. The engine responded very well and the clutch hooked up as it should with only the primary arms in the burn-out. Maybe the rpm:s went up a little bit to high, the wheel speed went up to 380 km/h (230 mph). It´s tricky to know the trottle response before you tried it. With a fuel pressure higher than it ever had been before we got a smaller leak from one hose and have to shut the engine off. We fixed the leak easy but as the rules are we miss that run.

Next day rain and wind and the day after that also rain. Not one single round in the European Championship, cars or bikes, could be completed because of the rain.

So we did not qualify and even if we did not get a run it gave us a lot. Just a burn-out and the data we got from it shows that we are on the right track. We did work in the pit for three days starting tuning testing to get a basic setup and also get all functions to work properly.

Since September last year when we started the bike for the first time we have been doing many changes. Here is a few examples. The main thing is a new designed mounting of the front primary drive pulley to the crankshaft. The McClure Overkill crank is modified to fit the new mounting and the main bearings in the crankcase is moved to give more room for the mounting.

The engine also have got improved lubrication system with some new ports inside the Overkill crankcase. Both the feed and return is changed to get better circulation and less outside hoses. The Autoverdi oil-pump is doing its job and the oil pressure variation is only 5 psi from idle 3000 rpm up to 7000 rpm.

The Clutch Cannon is redesigned for other seals to prevent the air from coming into the oil.

The 44-amp Dual MSD Magneto Ignition have got improvements with waste spark boxes for the 14 plugs we not have on our two cylinder engine. It helps to keep the spark energy up.

These new designed or modified components seems to work very well and we are sure there will be more when we get more runs on the bike. We now look forward to the next event in Finland in July. But before that, coming weekend Custom Bike Show in Norrtälje SWEDEN.

It has been a long way, from idea, planning, designing, chasing parts and manufacturing to get there, the first time open the trottle at the track. The list of involved people is so long that it needs a separate story to describe how the work has been done and by whom.

Two days before the event was spent in the pits by the team starting and testing systems and set-ups. The team was Jarmo Pulkkinen, Mats Tärnström, Carina and Charley. Hans Björkman, machinist and inventor who has spent days and nights in the Karling workshop together with Mats and Charley, stayed at home following the event. The Super Twin Rider Greger Johansson was also in team for the weekend and will also be so in Finland. Greger is making new engines and will be out later during the summer. Christian and Viktoria now with the little daughter Liv and changes in work situation do not have the time to spend the time that is needed.

We did miss the first qualification session because we did not get the right temperature at the rear cylinder. On the second session we were out. The engine responded very well and the clutch hooked up as it should with only the primary arms in the burn-out. Maybe the rpm:s went up a little bit to high, the wheel speed went up to 380 km/h (230 mph). It´s tricky to know the trottle response before you tried it. With a fuel pressure higher than it ever had been before we got a smaller leak from one hose and have to shut the engine off. We fixed the leak easy but as the rules are we miss that run.

Next day rain and wind and the day after that also rain. Not one single round in the European Championship, cars or bikes, could be completed because of the rain.

So we did not qualify and even if we did not get a run it gave us a lot. Just a burn-out and the data we got from it shows that we are on the right track. We did work in the pit for three days starting tuning testing to get a basic setup and also get all functions to work properly.

Since September last year when we started the bike for the first time we have been doing many changes. Here is a few examples. The main thing is a new designed mounting of the front primary drive pulley to the crankshaft. The McClure Overkill crank is modified to fit the new mounting and the main bearings in the crankcase is moved to give more room for the mounting.

The engine also have got improved lubrication system with some new ports inside the Overkill crankcase. Both the feed and return is changed to get better circulation and less outside hoses. The Autoverdi oil-pump is doing its job and the oil pressure variation is only 5 psi from idle 3000 rpm up to 7000 rpm.

The Clutch Cannon is redesigned for other seals to prevent the air from coming into the oil.

The 44-amp Dual MSD Magneto Ignition have got improvements with waste spark boxes for the 14 plugs we not have on our two cylinder engine. It helps to keep the spark energy up.

These new designed or modified components seems to work very well and we are sure there will be more when we get more runs on the bike. We now look forward to the next event in Finland in July. But before that, coming weekend Custom Bike Show in Norrtälje SWEDEN.

onsdag 23 april 2008

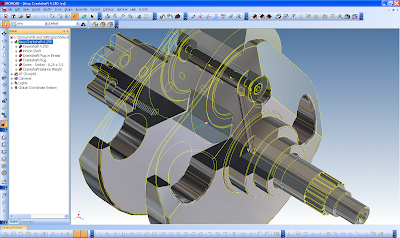

2008-04-23 Balancing our new Crankshaft with IronCAD

The Karling Racing Team has been using IronCAD 3D for all designwork and documentation for the new dragbike.

In the latest version of IronCAD is the COG (Center of gravity) tool available. With the part or parts in an assembly marked and clicking on the COG icon does it take a second or two for the program to position a small dot in the weight center of the object. If selected, the position of the weight center also is shown.

The picture shows that the weight center is only 0,500 from the centerline of the crank when a calculated counterweight is added temporary to the crankpin. By taking away or add material at the right place does the weight center position move.

If you want a 30 days trial licence of IronCAD call Solidmakarna Sweden National at 08-556 185 40 or International +46-8-556 185 40.

You can also go into http://www.solidmakarna.se/ or http://www.ironcad.com/ and order a trial download.

Refer to Karling Racing Team when sending your request or calling.

In the latest version of IronCAD is the COG (Center of gravity) tool available. With the part or parts in an assembly marked and clicking on the COG icon does it take a second or two for the program to position a small dot in the weight center of the object. If selected, the position of the weight center also is shown.

The picture shows that the weight center is only 0,500 from the centerline of the crank when a calculated counterweight is added temporary to the crankpin. By taking away or add material at the right place does the weight center position move.

If you want a 30 days trial licence of IronCAD call Solidmakarna Sweden National at 08-556 185 40 or International +46-8-556 185 40.

You can also go into http://www.solidmakarna.se/ or http://www.ironcad.com/ and order a trial download.

Refer to Karling Racing Team when sending your request or calling.

torsdag 17 april 2008

fredag 4 april 2008

Feb 8th 2008 SWEDISH RALLY AND UDDEHOLM SEMINAR SWEDEN

SWEDISH RALLY & UDDEHOLM SEMINAR SWEDEN

At this years Uddeholm Automotive Tooling Seminar at Selma Spa in Sunne could we proudly present the new Uddeholm/Karling dragbike. Almost 200 people did participate at the seminars and also visit the World Championship Rally that was taking place close to the seminar days.

A handful seminars were held by Automotive Industry people. The former race car driver Kenny Bräck today host Tv shows did present his projects developing young talent race car drivers. David Richards chairman of Prodrive (Subaru Rally Team) and Aston Martin did talk about the future for some areas within motorsport and automotive industry.

After the general sessions did parallel sessions take place and at one of those did the Uddeholm HPS have a presentation in wich the focus were racing. Dick Kymäläinen who is HPS business area manager did open up the session. As one part of the session did Charley present his background but the main subject was new bike and how the Karling Race Team developed it.

At this years Uddeholm Automotive Tooling Seminar at Selma Spa in Sunne could we proudly present the new Uddeholm/Karling dragbike. Almost 200 people did participate at the seminars and also visit the World Championship Rally that was taking place close to the seminar days.

A handful seminars were held by Automotive Industry people. The former race car driver Kenny Bräck today host Tv shows did present his projects developing young talent race car drivers. David Richards chairman of Prodrive (Subaru Rally Team) and Aston Martin did talk about the future for some areas within motorsport and automotive industry.

After the general sessions did parallel sessions take place and at one of those did the Uddeholm HPS have a presentation in wich the focus were racing. Dick Kymäläinen who is HPS business area manager did open up the session. As one part of the session did Charley present his background but the main subject was new bike and how the Karling Race Team developed it.

Jan 9th to 11th 2008 AUTOSPORT INTERNATIONAL SHOW BIRMINGHAM ENGLAND

AUTOSPORT INTERNATIONAL SHOW BIRMINGHAM ENGLAND

For the first time did Uddeholm UK participate at the Autosport International Show at NEC in Birmingham see www.autosport-international.com. The show is spread out at 13 halls wich is making it the largest motorsport exhibition in the world.

The two first days was open for industry professionals only and the two following weekend days did the doors open up for for the general public.

The dragbike did a very good job to bring in people to the display in. We could see that the Uddeholm brand is being more and more well known in the racing industry.

For the first time did Uddeholm UK participate at the Autosport International Show at NEC in Birmingham see www.autosport-international.com. The show is spread out at 13 halls wich is making it the largest motorsport exhibition in the world.

The two first days was open for industry professionals only and the two following weekend days did the doors open up for for the general public.

The dragbike did a very good job to bring in people to the display in. We could see that the Uddeholm brand is being more and more well known in the racing industry.

Nov 23rd to 25th 2007 BILSPORTMÄSSAN ÄLVSJÖ STOCKHOLM

BILSPORTMÄSSAN ÄLVSJÖ STOCKHOLM

To represent dragracing with motorcycles were the dragbike on display together with Göran Persåker Top Fuel Car, Mats Eriksson Pro Mod and Ludde Perez Junior Dragster. During the exhibition days were 23 000 visitors at the show. Read more at http://www.bilsportmassan.se/.

To represent dragracing with motorcycles were the dragbike on display together with Göran Persåker Top Fuel Car, Mats Eriksson Pro Mod and Ludde Perez Junior Dragster. During the exhibition days were 23 000 visitors at the show. Read more at http://www.bilsportmassan.se/.

Nov 22nd to 23rd 2007 SACO STUDENTMÄSSA ÄLVSJÖ STOCKHOLM

SACO STUDENTMÄSSA ÄLVSJÖ STOCKHOLM

This show is to attract students to search for education in Universities in Sweden. As an “eye-opener” did we have the new dragbike at display in the boot for Bergsskolan (University that educate for among of others Masters of Metallurgy). Bergsskolan is located in Filipstad see http://www.bergsskolan.se/.

This show is to attract students to search for education in Universities in Sweden. As an “eye-opener” did we have the new dragbike at display in the boot for Bergsskolan (University that educate for among of others Masters of Metallurgy). Bergsskolan is located in Filipstad see http://www.bergsskolan.se/.

Prenumerera på:

Kommentarer (Atom)